We provide cost-efficient, agile expertise in Industrial Performance & Commercial Development Internationally

We help manufacturers to develop internationally while increasing their profits by improving their industrial performance

SNECI is the global leader in improving industrial and commercial performance internationally.

With roots in the automotive industry, a true industry of excellence, we apply our expertise across industries, from pharmaceuticals to railways and aeronautics, energy and luxury.

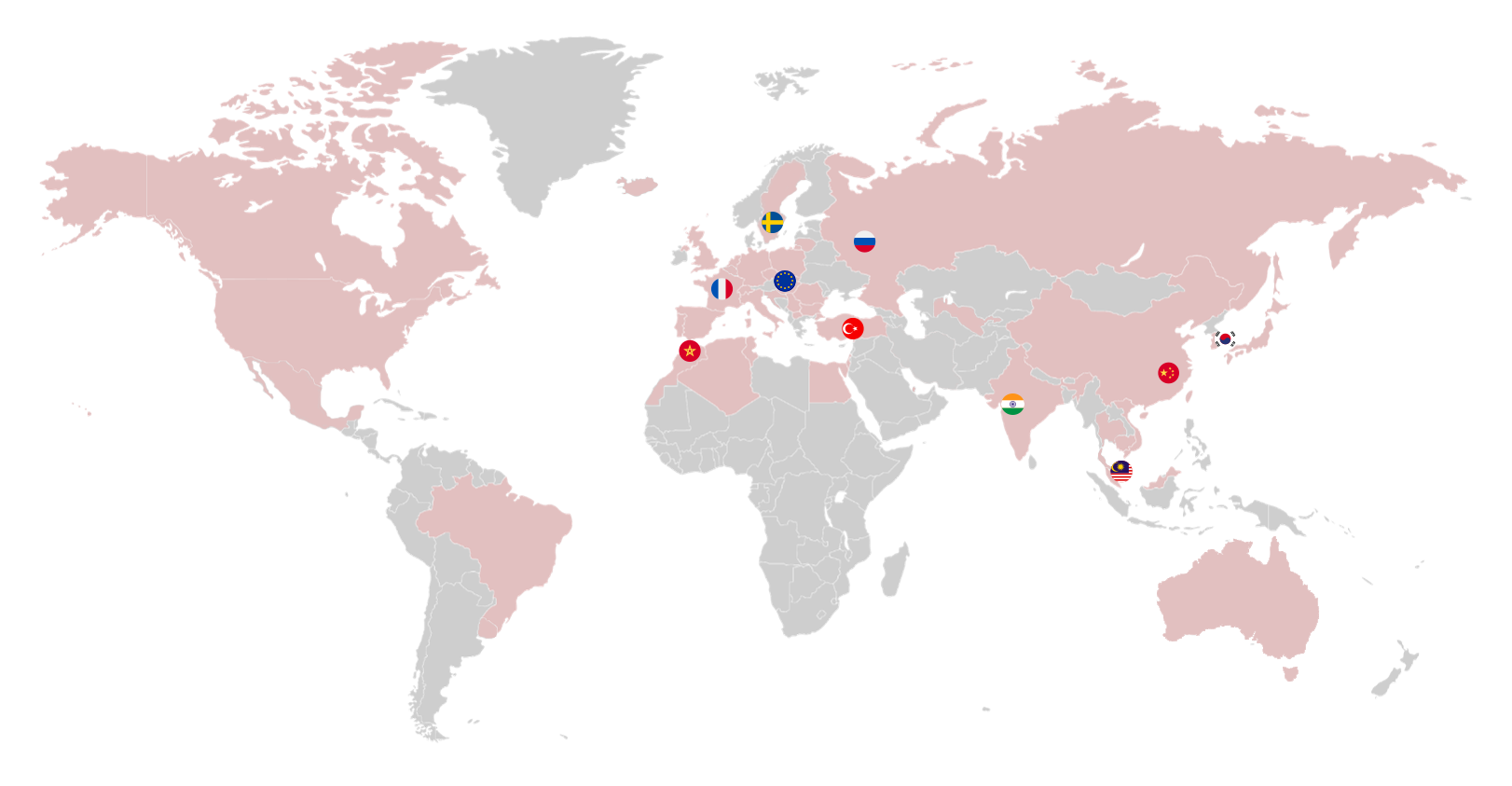

With our own offices in ten countries, we understand and resolve issues linked to international development, providing local solutions to our industrial customers.

As a family-owned company focused on the success of our clients, our teams are experts in their fields, following each project with the greatest attention, from winning new markets to setting up your industrial operations.

SNECI is an award winning ISO 9001:2015 and ECOVADIS Silver for our CSR approach.

Find Out More About SNECI

We are SNECI. An international family-owned service and consulting company with 70 years of experience in many industries. Through our global presence, with offices in 10 countries, we serve over 400 industrial companies worldwide. Our mission: to improve the industrial and commercial performance of our clients internationally.

THEY TRUST US

Join our 400+ customers

In automotive

Other Industries

Our network of trusted partners

OUR VALUES

Initiative and Tenacity

Relationship building

Stretching yourself

Collective engagement