我们在商业开发和国际绩效方面提供经济高效、灵活的专业知识

我们帮助制造商进行国际化发展,同时通过提高工业性能来增加利润。

思能新是在国际上提高工业与商业绩效的全球领导者。

我们扎根于汽车行业这一卓越的行业,将我们的专业知识应用于各个行业,从制药到铁路与航空、能源与奢侈品。

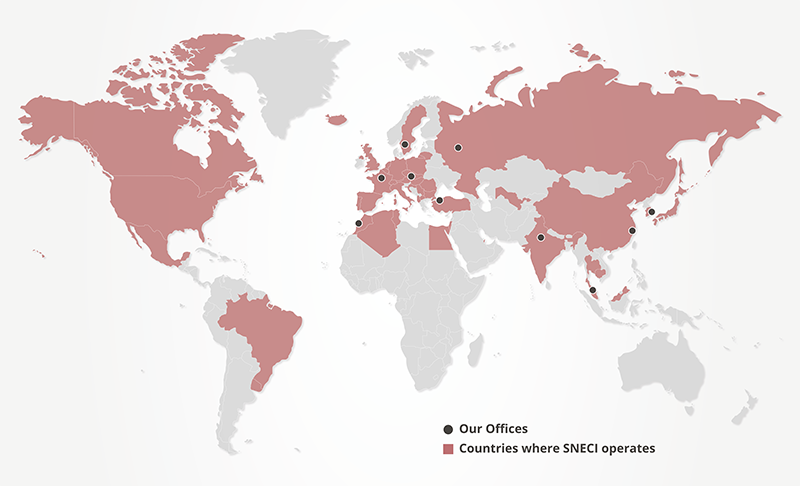

我们在十个国家建立了自己的机构,使我们能够了解与国际发展相关的问题,并为工业客户的问题提供当地的解决方案。

作为一家专注于客户成功的家族企业,我们的团队由各领域的专家组成,从赢得新市场到建立您的工业运营,我们对每个项目都非常关注。

思能新获得了ISO 9001:2015和ECOVADIS银质奖,以表彰我们的企业社会责任做法。

关于SNECI

我们是思能新。一家国际家族式服务与咨询公司,在许多行业拥有70年的经验。我们的业务遍及全球,在10个国家设有办事处,为全球400多家工业企业服务。我们的使命:在国际上提高客户的工业和商业绩效。

请相信我们

加入我们的400多个客户

在汽车行业

其他行业

我们值得信赖的合作伙伴网络

我们的价值

主动性和韧性

建立关系

伸展自己

集体参与