Auditor role and supply chain management

Nowadays auditors working in the automotive industry with suppliers are usually fully loaded. Time for projects and reaction has significantly shrunk. This definitely impacts the planning, performance and feedback of the audits. Nevertheless we should always remember and try to keep the best practices during audits, which we have summarized below:

Supplier auditing guide

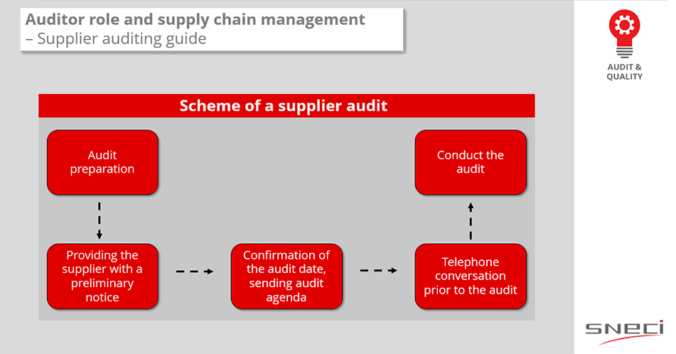

Scheme of a supplier audit

- Audit preparation

- Providing the supplier with a preliminary notice including the date, scope of the audit, the key issues and the documents that should be made available for the duration of the audit or sent prior to its commencement

- Confirmation of the audit date and sending the audit agenda

- Prior to the planned audit, a telephone conversation with the supplier should take place

- Conducting the audit

To be kept in mind:

- We are conducting the audit, not the other way around

- The workers should be interviewed as well as the leaders and directors

- The focus should not be on irrelevant issues (this could lead to overlooking the more relevant aspects of the process due to the time limit)

- All findings should be recorded

- If possible, the 2nd and 3rd shifts should be inspected as well

- The information obtained should always be substantiated with evidence. The knowledge of the location of the records, who is responsible for filling them in and supervising them should be acquired.

- Suitable notes should be taken regarding any documentation that needs to be inspected but is not accessible during the line check.

- It should be noted who is in charge of answering the open questions, providing the required documents or implementing immediate corrective actions.

Summary

- Using a prepared outline will make the auditing process more thorough, eliminate unnecessary stress on both sides and help to prevent problematic situations (e.g. lack of knowledge regarding the processes or issues )

- All observations should be documented. The notes should include the date, time, the person in charge, what documents have been looked at and if any issues have been encountered

- All questions should be asked in a form of an open question as it helps to obtain the broad information, which usually requires more detailed explanations. Examples of such questions include: ‘could you please tell me…? ‘(who, what, where, why, when, how) and ‘could you please show me….?’

- First and foremost, the focus should be on investigating the process and relating the findings to the required documents, process supervision, staff training and compliance with the quality system.

If you struggle with your suppliers or need expertise to develop your suppliers, SNECI has all the expertise to make your supply chain successful through supplier development, coaching, on-site interim management, resident engineering.